Daily usage specifications for generators

Daily usage specifications for generators

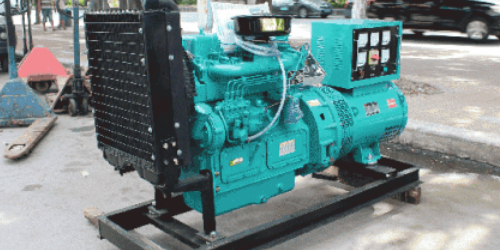

In usedynamoWhen using the generator, the operating process plays a key role. It should be used strictly in accordance with the operating instructions. A comprehensive inspection must be carried out before use to prevent damage to the generator and thus affect production. During use, attention should be paid to observation in order to prevent electrical accidents. Occurs. After use, the generator must be inspected. The generator must be cooled after operation and sorted for next use.

1. Things to check before use

When facing a sudden power outage, professional personnel should start the generator and conduct a comprehensive inspection of the generator before use. First, check the amount of engine oil in the generator and whether the oil is in the appropriate level of the generator. Within the dosage range, it should not be too high or too low. Check the color of the engine oil. From the color and viscosity, you can see whether the oil meets the working needs of the generator. Secondly, if the generator is working in a low temperature environment, pay attention to Check whether the antifreeze in the machine is qualified and whether the content is within the specified range of the machine. Check whether the water tank cover is well sealed and whether the fuel is sufficient for the generator. Again, professionals should confirm whether the power output circuit breaker is in the off state. open state, which is related to safety issues, so inspections should be focused. Finally, the staff should make a comprehensive observation of the appearance of the machine. If oil leakage or line damage is found, the start-up work should be terminated and the damaged parts of the machine should be repaired until Only after the repair is completed and confirmed to be correct can the start-up procedure be entered. This complex pre-start inspection procedure is a necessary step for using the generator and is of great significance to the safe use and working status of the generator.

2. Boot steps

After checking that the machine equipment is correct, you can start it up. During the startup process, you must also follow the operating procedures. The first step is to open the protective door of the control panel of the generator and keep the safety switch device in the closed state. Step 2, turn on the indicator light to test the button. If all the indicator lights are on, it means that the machine is normal and you can proceed to the next step. However, when the indicator light flashes or becomes unresponsive, the staff is required to stop the next step, and The generator must be inspected and repaired after finding the cause. After the repair is completed, turn on the indicator light test button again and perform a retest. The indicator light test is a necessary measure to run the generator, which can prevent forced starting of the machine and damage to the generator system. Cause impact. Step 3, press the warning light, the work light is always on, and other indicator lights are off. At this time, you can operate the start button. After a short wait, the generator can start on its own. After the generator is running normally, you need to Use the machine's operation panel to check the machine's oil, temperature, speed, voltage and other data to determine whether the generator is running normally. After the generator starts and starts power supply, the staff should always observe the power supply status of the generator. .Track and observe the voltage and current output frequency to ensure that the generator operates smoothly during the power supply process.

3. Precautions for shutdown

Cooling process, and finally pull down the safety. With the development of modern science and technology, the safety of the machine is becoming more and more important. When using the generator, an emergency stop is also set up.When facing an emergency, the emergency stop button can stop the machine immediately, thereby ensuring safe production. The generator is operating normally.When shutting down, be sure to let the generator cool down and shut down on its own. This method can effectively protect the generator equipment and increase the durability and longevity of the machine.It can also provide good protection for the next use of the generator.